The Alpha XS – Precision CNC Combination Lathe

Toolroom Accuracy, Maximum Productivity

The Harrison Alpha XS delivers the flexibility of a manual lathe with the productivity of CNC. Built to exacting DIN 8605 toolroom accuracy standards, it guarantees outstanding repeatability, exceptional surface finish, and lower component production costs.

From prototypes and one-offs to small and medium batch runs, the Alpha XS is engineered to adapt seamlessly to your workflow.

Also known as a combi lathe, hybrid lathe, or manual/CNC lathe, it’s the ideal choice for workshops, training centres, and toolrooms that demand precision and versatility.

Five Modes of Operation – One Control

Powered by a customised Fanuc 0i-TF Plus CNC control, the Alpha XS combines an industry-standard platform with Colchester’s shop-floor innovation. Trusted worldwide, it integrates smoothly into modern workflows while reducing training time and protecting long-term investment.

Choose from five operating modes at the turn of a key:

- Manual Mode – Conventional operation with DRO-style displays, spindle speed, and feed rate. Perfect for skilled machinists and apprentices.

- Alpha System (Conversational Mode) – Colchester’s acclaimed Q&A interface for cycle-based programming. Learn in under half a day.

- Manual Guide i (Automatic Mode) – Fanuc conversational CNC with 3D simulation, toolpath animation, and automatic G-code generation.

- AlphaLink (Offline Programming) – Create ISO G-code in any CAD/CAM system and transfer it directly to the machine.

- Full CNC Mode – Write or import standard G-code directly at the control for complex or repeat components.

This flexibility makes the Alpha XS as easy to use for one-off jobs as it is for repeat CNC production.

Built for Toolrooms, Trusted Worldwide

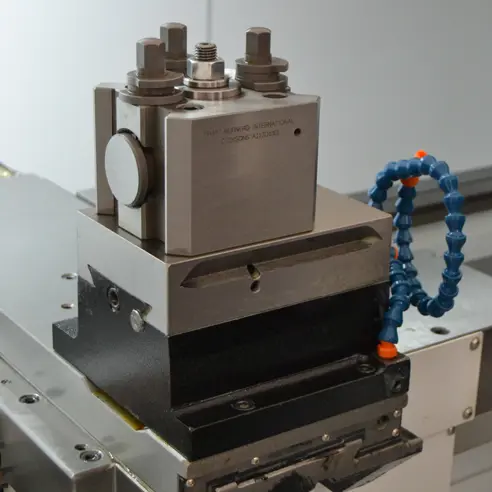

The Alpha XS is a flat bed horizontal CNC lathe that combines rigidity, stability, and accessibility. With bed lengths from 650 mm to 6 m, spindle bores up to 155 mm, and drive motors from 7.5–18.5 kW, it can handle everything from small precision parts to long, heavy workpieces.

Adopted by manufacturers, colleges, and training centres worldwide, the Alpha XS is ISO-code compatible and supports AlphaLink multi-desk training, making it as effective in classrooms as it is on the shop floor.

Engineered by Lathe Specialists

Colchester’s engineering expertise makes the Alpha System unique:

- Fast tool setting in three screens with automatic offsets

- Semi-automatic cycles for threads, radii, grooves, tapers, and contours

- Manual override for full operator confidence and control

- Custom-developed cycles to cut setup time

- Touchscreen simplicity for shop-floor ease of use

Even operators returning after years away can start machining confidently in minutes.

Smart CNC with Powerful Simulation

Manual Guide i transforms the Alpha XS into a fully capable horizontal CNC lathe. Build CNC programs in the background while programming conversationally, simulate in 3D, and verify toolpaths before cutting.

Import CNC programs from external systems or generate new code to share with other machines—the Alpha XS makes it easy.

The Colchester Advantage

The Alpha XS is the most versatile combination lathe Colchester has ever produced. It adapts to your workflow, amplifies operator skills, and delivers measurable productivity gains—often doubling or tripling output compared to conventional methods.