The Alpha XS & XC Series – The World’s Most Versatile CNC Combination Lathes

Precision Turning, Simplified

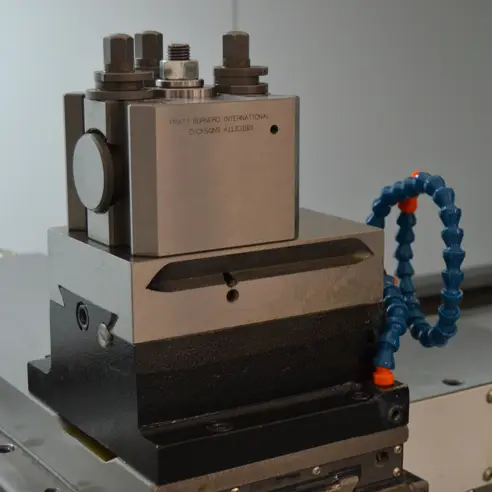

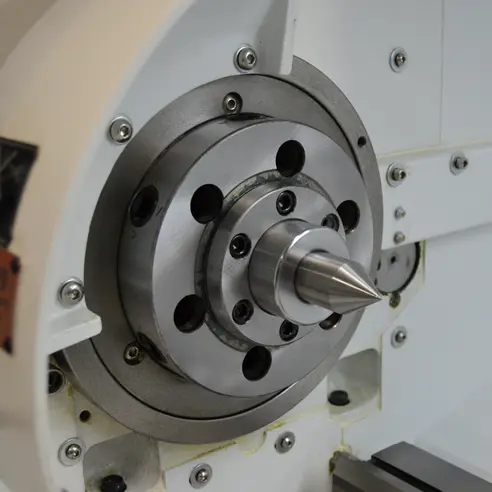

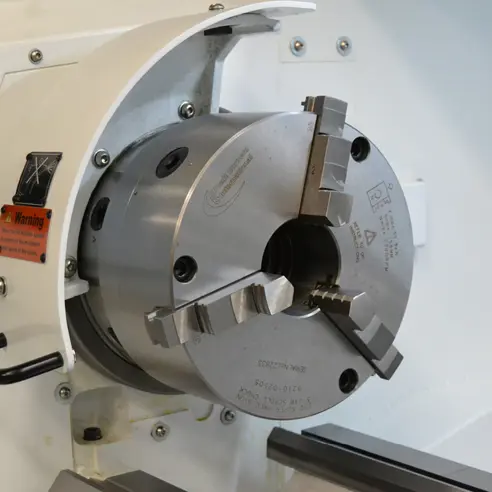

The Harrison Alpha XS and Alpha XC ranges deliver the perfect balance of manual control and CNC productivity. Designed and built to DIN 8605 toolroom accuracy standards, Alpha lathes guarantee high repeatability, exceptional surface finish, and reduced component costs.

From one-off prototypes to small and medium batch runs, the Alpha range adapts seamlessly to your workflow, offering the flexibility of a manual/CNC combination lathe with the performance of a full CNC machine.

The Alpha XC – MillTurn Flexibility with C-Axis and Driven Tools

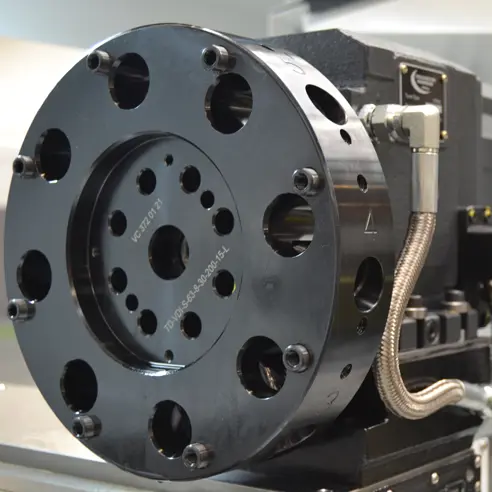

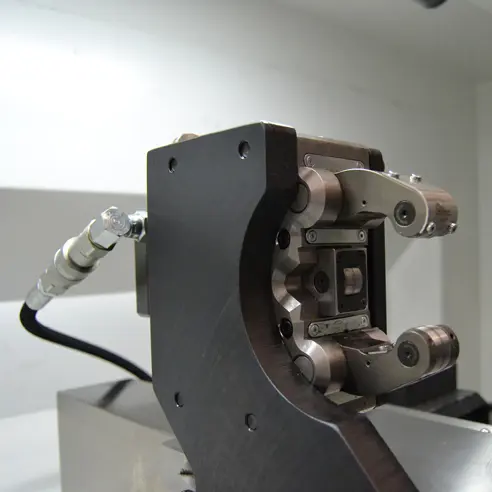

The Alpha XC extends the Alpha platform with full 3-axis machining, including C-axis control and driven tooling. This transforms the machine into a true MillTurn lathe, combining turning, milling, drilling, and tapping in one setup.

- Eliminate second operations

- Reduce handling and downtime

- Produce complex components faster and more accurately

Whether you need bolt-hole patterns, keyways, or multi-featured prototypes, the Alpha XC saves time while maintaining toolroom-grade precision.

Five Operating Modes – One Control Platform

Both Alpha XS and XC machines feature the proven Fanuc 0i-TF Plus touchscreen control—an industry-standard CNC platform trusted worldwide for reliability and compatibility.

Operators can choose from five powerful modes at the turn of a key:

- Manual Mode – Operate as a conventional lathe with DRO-style readouts, handwheel control, and spindle data.

- Alpha System (Conversational Mode) – Colchester’s intuitive, Q&A-based teach lathe software. Learn in under half a day.

- Manual Guide i (Automatic Mode) – Fanuc’s advanced conversational CNC with 3D simulation, toolpath animation, and instant ISO G-code generation.

- AlphaLink (Offline Programming) – Use your preferred CAD/CAM package to prepare G-code and transfer it directly to the machine.

- Full CNC Mode – Write or import complete ISO G-code programs directly at the control—ideal for repeat and complex jobs.

This flexibility allows operators of all experience levels to choose the right workflow for every component.

Designed for Today’s Workshop

The Alpha range is ideal for high-mix, low-volume environments where flexibility is key.

- XS models: 2-axis turning with bed lengths from 650 mm to 6 m, spindle bores up to 230 mm, and spindle drives from 7.5 kW to 18.5 kW.

- XC models: 3-axis MillTurn capability with driven tooling and C-axis for complete machining in one setup.

As flat bed horizontal CNC lathes, both XS and XC deliver outstanding rigidity, thermal stability, and easy access for operators.

Proven in Industry and Training

Alpha lathes are the machine of choice for manufacturers, repair shops, training centres, and universities worldwide. Their combination of ISO-standard CNC compatibility, fast setup, and intuitive operation makes them equally suited to production floors and classrooms.

With AlphaLink multi-desk training, instructors can deliver CAD/CAM lessons directly into the workshop environment.

The Colchester Advantage

With over 100 years of British engineering excellence, Colchester delivers more than machines—we provide complete turning solutions, supported in over 60 countries.